Safe Sorting - Superior Waste Recycling Robots

Get more value out of waste with ZenRobotics. We have been serving frontrunning recycling companies since 2007, using Artificial Intelligence (AI) to automate waste sorting and make outdated, inefficient and unsafe manual sorting a thing of the past with safe sorting robots.

Your operations stand to benefit from AI-based sorting, whatever your starting point.

Whether you want to modernize your existing facility with smart robotics or invest in a new fully automated recycling plant, we have you covered. Here are three options for how you can robotize and automate your waste operations, as demonstrated by several

operators around the world here

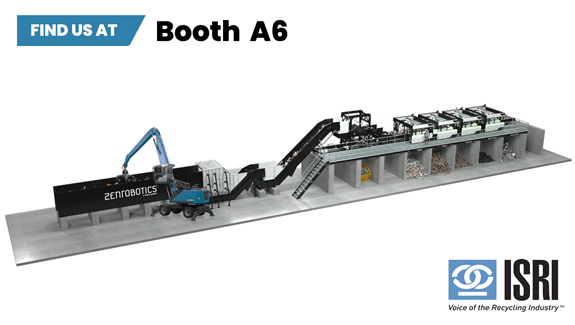

ZenRobotics has the right robot for every sorting need. The Heavy Picker for bulky waste like C&D, the Fast Picker for light packaging waste and an all might industrial AI with more than a decade of experience from recognising and sorting high quality recyclables from around the world.

Meet Our Robots

Our robots are helping operators in 15+ countries worldwide to extract higher value out of waste, get actionable data and reach ambitious circular economy goals.

Latest News

Keep up to date with the latest industry news and events.

.png?sfvrsn=48509761_0)

_sept-22.png?sfvrsn=d50e5aa3_1)

_sept-22.png?sfvrsn=ea871683_1)

_sept-22-(1).png?sfvrsn=c72ae160_4)

_sept-22.png?sfvrsn=3da281d3_1)

_sept-22.png?sfvrsn=4586020_1)

_sept-22_new.png?sfvrsn=1c2a716a_1)

_sept-22.png?sfvrsn=fac2d11a_0)

_sept-22.png?sfvrsn=d15cd8d_1)

_sept-22.png?sfvrsn=60c3f49b_1)

_sept-22.png?sfvrsn=a5c9b887_1)